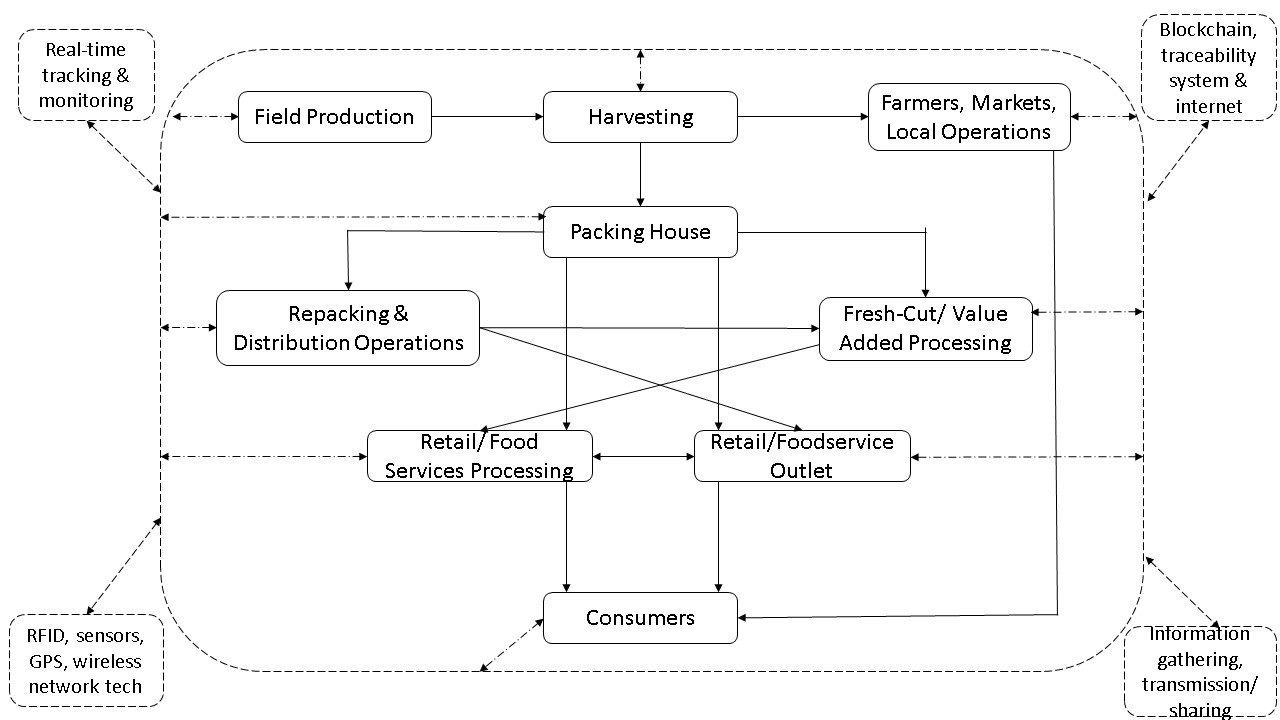

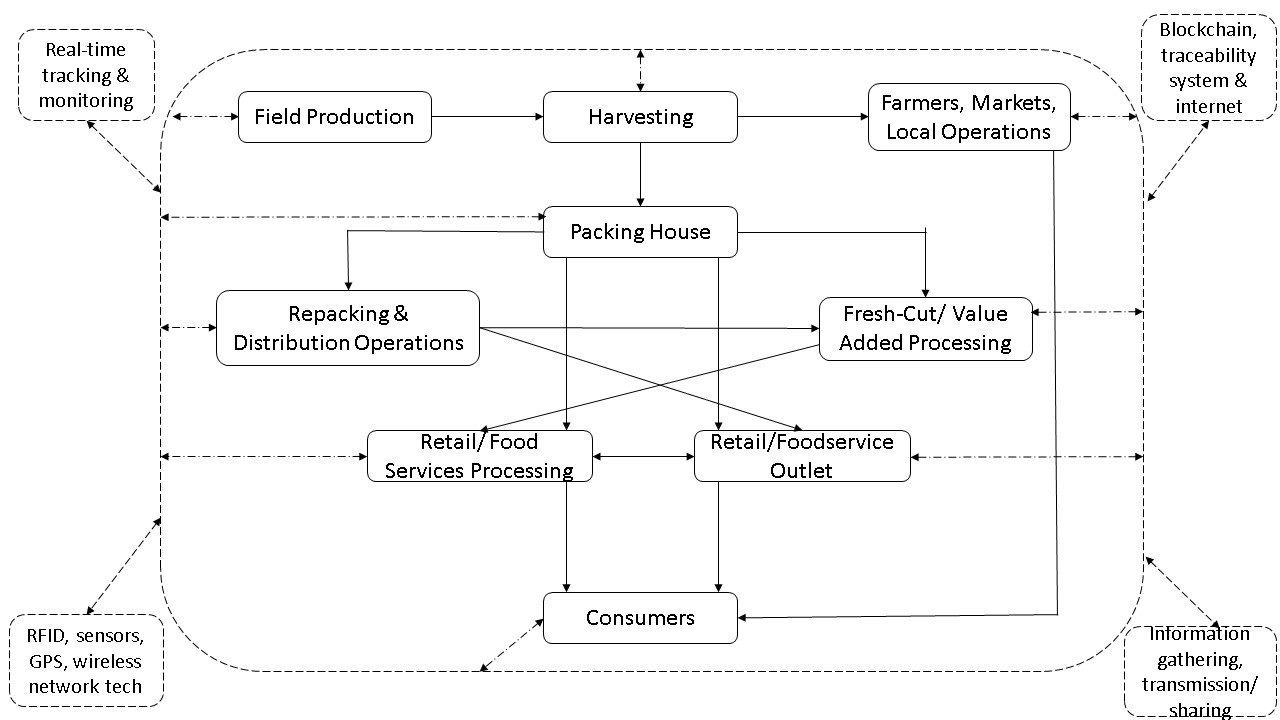

The melon traceability system is dependent on the adoption of RFID (radio frequency identification) technology, which is a noncontact automatic identification communication technology that can identify multiple, high-speed moving objects simultaneously in most environmental conditions.

This technology has been widely used throughout the agriculture supply chain, with broadest adoption in the livestock industry. It has been successfully implemented in vertically integrated supply chains to track and monitor food from producer to wholesaler to retailer to consumer.

The traceability system creates a reliable database that is either collectively maintained through a decentralized and trustless method or is maintained through a centralized database (like the one being implemented by IBM in partnership with Walmart and the IBM Food Trust).

A blockchain system relies on the following: decentralization, as no organization owns the whole network; a trustless, open source system; collectivity, as all nodes (members of the chain) register and input data; and reliability of the database, with every node receiving a complete copy of the database with anonymity (nodes do not know the identity of other nodes).

While this has worked to some extent in the livestock industry, it is more challenging to implement in the fresh fruit and vegetables sector. Thus, a traceability system that is a variant of blockchain, using RFID, was found to be more likely solution for the melon industry.

Challenges to Implementation

Unfortunately, RFID technology has a high cost of adoption. Projects funded through land-grant institutions provide some opportunities in leveling the playing field for small- and mid-sized farmers to be able to market high-quality differentiated products. The minimum cost of an individual RFID tag is 30 cents in the United States but cheaper in China. Secondly, the traceability system itself also invokes additional equipment and programming costs.

Blockchain performance and development is not yet where it needs to be for full implementation of a decentralized, trustless, anonymous network to function as described above. The biggest challenges are technological. Producers face blockchain scalability, speed, and transaction challenges as well as a lack of agreement on what type of blockchain technology should be adopted.

Standardization and privacy are also huge challenges for extended produce supply chains with multiple participants. In the melon industry, the vast amount of manual paper transactions provides another obstacle to collecting and tracking off-chain data.

Finally, without top management support, user resistance provides a huge barrier to small and medium sized firms considering traceability systems adoption.

Without an innovative culture, the standard practices of farming, production, packaging, and distribution are liable to continue in a market with labor shortages and slow technological development and adoption.

This is multi-part feature adapted from the January/February 2020 issue of Produce Blueprints.

The melon traceability system is dependent on the adoption of RFID (radio frequency identification) technology, which is a noncontact automatic identification communication technology that can identify multiple, high-speed moving objects simultaneously in most environmental conditions.

This technology has been widely used throughout the agriculture supply chain, with broadest adoption in the livestock industry. It has been successfully implemented in vertically integrated supply chains to track and monitor food from producer to wholesaler to retailer to consumer.

The traceability system creates a reliable database that is either collectively maintained through a decentralized and trustless method or is maintained through a centralized database (like the one being implemented by IBM in partnership with Walmart and the IBM Food Trust).

A blockchain system relies on the following: decentralization, as no organization owns the whole network; a trustless, open source system; collectivity, as all nodes (members of the chain) register and input data; and reliability of the database, with every node receiving a complete copy of the database with anonymity (nodes do not know the identity of other nodes).

While this has worked to some extent in the livestock industry, it is more challenging to implement in the fresh fruit and vegetables sector. Thus, a traceability system that is a variant of blockchain, using RFID, was found to be more likely solution for the melon industry.

Challenges to Implementation

Unfortunately, RFID technology has a high cost of adoption. Projects funded through land-grant institutions provide some opportunities in leveling the playing field for small- and mid-sized farmers to be able to market high-quality differentiated products. The minimum cost of an individual RFID tag is 30 cents in the United States but cheaper in China. Secondly, the traceability system itself also invokes additional equipment and programming costs.

Blockchain performance and development is not yet where it needs to be for full implementation of a decentralized, trustless, anonymous network to function as described above. The biggest challenges are technological. Producers face blockchain scalability, speed, and transaction challenges as well as a lack of agreement on what type of blockchain technology should be adopted.

Standardization and privacy are also huge challenges for extended produce supply chains with multiple participants. In the melon industry, the vast amount of manual paper transactions provides another obstacle to collecting and tracking off-chain data.

Finally, without top management support, user resistance provides a huge barrier to small and medium sized firms considering traceability systems adoption.

Without an innovative culture, the standard practices of farming, production, packaging, and distribution are liable to continue in a market with labor shortages and slow technological development and adoption.

This is multi-part feature adapted from the January/February 2020 issue of Produce Blueprints.

Hannah Stolze is associate professor of marketing and supply chain management at Wheaton College in Wheaton, IL, and has a PhD in business administration with a concentration in logistic and marketing.