The U.S. Food and Drug Administration (FDA) approved ozone for use in either gaseous (air) or aqueous (water) forms. Ozone equipment then adjusts the output to create a product at the correct parts per million (ppm) for the manner in which the ozone will be used.

Measuring Multiple Benefits

Fred Recchiuti, general manager at Avondale, PA’s Basciani Foods, says ozone is in the water the company uses to sanitize their mushroom growing operations and cites the company’s sustainability initiative as part of the reason.

The Environment and Chemical Usage

The Environment and Chemical Usage

“We’re trying to get as far away from chlorine as possible,” Recchiuti remarks. “No matter how well you capture the waste water, eventually the dioxins get into the tributaries and streams, eventually the bays and rivers. The fish will uptake the dioxins and it’s a carcinogen.”

In addition to environmental benefits, Recchiuti says ozone reduces the amount of chemicals they need to use.

“Ozone is a powerful sanitizer, but when (aqueous ozone is) exposed to air for a very short time, it just becomes water. We’ve found it to be very effective for preventing some discoloration of our mushrooms,” Recchiuti says. Better yet, he notes, “It’s just environmentally friendly.”

Exposure Risks

Hamil agrees, explaining that some companies use gaseous ozone in uninhabited areas of production facilities like ripening rooms.

Page 2 of 6«12345...»Last »

Food safety is top of mind in the produce industry, as everyone from growers to shippers to grocery stores look for ways to provide the healthiest fruits and vegetables to consumers.

While cleaning and sanitation has traditionally included chemicals to kill bacteria and contaminants, these come with their own safety and sustainability issues and provide no solution at all for organic growers. For a rising number of grower-shippers and suppliers, another solution has been gaining acceptance and producing results: ozone.

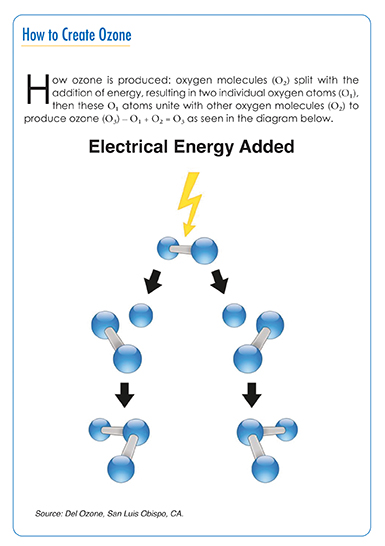

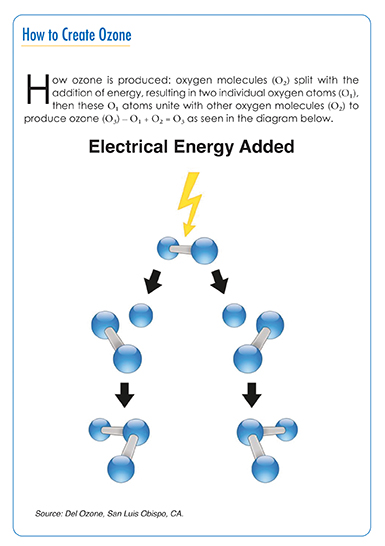

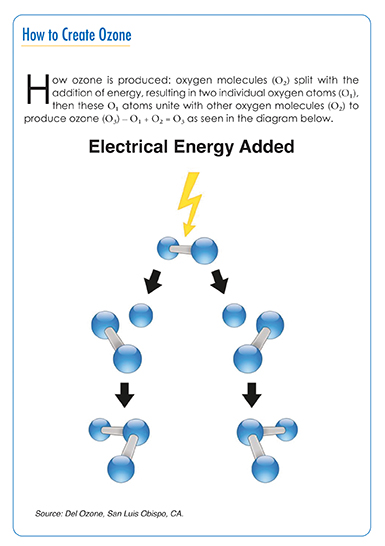

A Quick Trip back to Chemistry Class

Ozone has always been produced in nature, both by the sun’s ultraviolet rays and even by lightning. But, with a few simple ingredients, ozone can be manmade as well.

Although most people have probably heard of ozone, it is not in the most favorable light. While it is true ozone is a dangerous pollutant when found in the Earth’s lower atmosphere, there’s a flipside as well: ozone is also a valuable, beneficial part of the upper atmosphere.

So why should you care and what does it have to do with the fresh produce industry? The answer is simple: ozone can be a very effective oxidizing and sanitizing agent for perishables.

A Not-So-New Alternative

As far back as 2004, University of California, Davis professor Trevor Suslow (now director of the Postharvest Technology Center) wrote about its creation for use with postharvest fruits and vegetables. The article, “Ozone Applications for Postharvest Disinfection of Edible Horticultural Crops,” explained how specialized equipment could pass normal or oxygen-enriched air across an ultra violet light source, or use high electric voltage to create ozone.

Beth Hamil is the vice president of corporate operations and a food safety consultant at DEL Ozone, in San Luis Obispo, CA. She explained that this process gives an extra charge to some of the air’s regular oxygen molecules (O₂), causing them to split. These single (O) molecules bond with normal oxygen molecules (O₂ + O) to create ozone (O₃)—for further information, see the sidebar and diagram on this page.

For oxygen, three’s a crowd, and that extra atom makes the ozone molecule unstable and highly reactive. This is a good thing for two reasons: first, when bacteria is exposed to ozone molecules, the extra atom jumps ship and attaches to the bacteria cells, causing them to burst and die.

Second, because ozone is so unstable, it breaks down quickly and easily, turning back into harmless oxygen.

In addition, Hamil relates that ozone has a very short half-life of seconds to hours, depending on the type and other factors.

Although ozone has been used for many years to disinfect municipal water, bottled water, and even swimming pools, it has only been used in direct contact with food for about two decades, after gaining federal approval.

The U.S. Food and Drug Administration (FDA) approved ozone for use in either gaseous (air) or aqueous (water) forms. Ozone equipment then adjusts the output to create a product at the correct parts per million (ppm) for the manner in which the ozone will be used.

Measuring Multiple Benefits

Fred Recchiuti, general manager at Avondale, PA’s Basciani Foods, says ozone is in the water the company uses to sanitize their mushroom growing operations and cites the company’s sustainability initiative as part of the reason.

The Environment and Chemical Usage

The Environment and Chemical Usage

“We’re trying to get as far away from chlorine as possible,” Recchiuti remarks. “No matter how well you capture the waste water, eventually the dioxins get into the tributaries and streams, eventually the bays and rivers. The fish will uptake the dioxins and it’s a carcinogen.”

In addition to environmental benefits, Recchiuti says ozone reduces the amount of chemicals they need to use.

“Ozone is a powerful sanitizer, but when (aqueous ozone is) exposed to air for a very short time, it just becomes water. We’ve found it to be very effective for preventing some discoloration of our mushrooms,” Recchiuti says. Better yet, he notes, “It’s just environmentally friendly.”

Exposure Risks

Hamil agrees, explaining that some companies use gaseous ozone in uninhabited areas of production facilities like ripening rooms.

While U.S. Occupation Safety and Health Administration (OSHA) laws limit the amount of gaseous ozone that workers can be exposed to, Hamil believes they should not be exposed to any at all. She recommends using it in sealed rooms and waiting until it has broken back down into oxygen before admitting workers into the area.

Enhancing Shelf Life

Another critical factor is that ozone, Hamil stresses, cannot be stored. “It must be generated and applied on-site.”

And since ozone sanitation is a cool-temperature process, storage rooms are ideal places to pump ozone gas, not only for sanitization, but to increase shelf life. “If you have ozonated air in the ripening room,” she notes, it can “inhibit any microbial growth.”

Precision is key. David McGrath, vice president of sales and marketing at Cocoa, FL-based Guardian Ozone, confirms the necessity to “monitor all systems remotely to ensure the precise concentration and dosage for the right amount of time.” Too little ozone has no impact, he says, and “too much ozone is not good for people or products.”

Christopher Ranch, LLC is headquartered in Gilroy, but has offices across the country. The California-based grower has been using ozone on its fresh garlic for over ten years.

Janette Codiga, vice president of food safety and compliance, says the company uses ozone both as an antimicrobial agent and to ensure the stated shelf life of its peeled garlic cloves.

Organic growers are interested in ozone as a chemical-free sanitizer as well, since they have fewer options than conventional produce growers.

Food Safety Implications

Yet another benefit of using ozone, according to Hamil, is that it eliminates microorganisms without leaving a residue and is more powerful than traditional chemicals. She adds that it also has the ability to remove pesticides and kills microorganisms, while simultaneously disinfecting any of the surfaces around it.

So you get the benefit of sanitizing the produce as well as the conveyor belt, floors, and drains. “It’s absolutely lethal to all microorganisms,” she emphasizes, and it can break down biofilms on facility surfaces. “Chlorine can kill the top layer, but listeria can grow beneath the surface.”

Compatibility

Codiga says ozone is also easier on machinery. “Prior to using the ozone system, we used a chlorine bath for the garlic. It was hard on the equipment and more pieces of equipment had to be repaired or replaced. The ozone system is much easier on the equipment.”

Suslow cautions, however, that facilities must be careful in evaluating equipment before implementing ozone. “Be concerned with compatibility of materials in and around ozone,” he notes.

“It’s highly reactive and therefore highly corrosive. If it’s in water systems, it’s not a big deal as long as you’re aware of it,” Suslow advises. And over time, he says ozone can degrade door and valve seals as well as brass fittings.

Overall Improvement

Hamil believes ozone improves the health of any facility, and claims “no plant in the world that has had a microorganism outbreak was using ozone.” She added that while microorganisms can build up a tolerance to traditional chemicals, they can’t build up a tolerance to ozone.

There are also no containers to lug around or dispose of, and ozone is safer for employees to work with, requiring no personal protection devices when used correctly.

Limitations

On the flip side, there are a few limitations. Suslow’s University of California study found that while gaseous ozone in storage rooms is effective, it is not reliable in wiping out infections that may reside “within or beneath the plant surface.”

Ozone is also not a be-all end-all for sanitation, but part of a process. It does not take the place of wash water or chlorine rinses.

Hamil affirms that ozone does not replace all chemicals. “You don’t wash with it, you sanitize with it. So you still need chemicals for washing. You still need to clean first, and then go back to sanitize.”

In some cases, she adds, items may not be prewashed, but sprayed with aqueous ozone and then have wax added for final shipment.

“In a nutshell, aqueous ozone is generally not used as a wash as its surfactant qualities are not as fast as a soap-based product,” explains Hamil, “but ozone is an extraordinarily powerful sanitizer.”

While gaseous ozone can be used in storage coolers to sanitize and extend shelf life, its effectiveness can also be impaired when produce is tightly packed in bins or cartons.

Taking the Leap

So if a supplier wants to use ozone, what’s the first step? As a food safety consultant, Hamil says she visits a prospective customer’s plant to evaluate how ozone might best be used within the operation, including the size of necessary machinery, the appropriate dosage, and best location(s).

“Be strategic,” Suslow says. “If you’re going to do a sizeable system, you have to do a very good analysis.” And this includes knowing what materials are compatible with ozone and if any equipment will need to be retrofitted before implementation.

System Requirements

Almost any operation using some type of wash water is a potential ozone user. The type of system recommended depends on multiple factors, including the size of the plant and water flow rate on the lines, which may vary from section to section.

But once the decision is made, it’s pretty simple. The machinery arrives, is installed, and all users need are power and water. Mobile units are also available.

“In a very small facility, we may use mobile units,” Hamil comments, which can be moved around the plant as needed. “The manufacturer designs a set point for the amount of ozone you want in the water, and it stays at that level.”

Costs Involved

There are costs to buy the equipment and to install it, as well as what Hamil called “commissioning,” a process of showing employees how to use the new system.

A major positive is longevity. “Machines last 20 years on average without a major overhaul, but it could be 40 years,” she notes, if major upgrades are made.

Complete ozone systems, including monitoring and the system controls included with each unit, range from as little as $10,000 up to $200,000 depending on the size of the operation. Maintenance costs, Hamil says, might range from $300 to $3,000 per year.

“It’s a significant upfront investment,” Recchiuti points out, “but it paid off for us fairly quickly. We never jump into a new technology or process or anything like this without first testing it on a small scale. We had very favorable results so we started using it.”

Realizing ROI

Recchiuti says Basciani Foods has had little retooling as the company chose to use aqueous ozone instead of gaseous, so it was just a matter of “hooking up to a machine, testing the parts-per-million, and getting it properly set.”

Christopher Ranch’s Codiga calls the company’s ozone operation “a very simple system; it’s less harsh on the environment, our employees, and equipment. Overall,” she continues, “we feel it is a safer product.”

Recchiuti describes the system as “low maintenance” and has no regrets. “I look at it as payback on investment. For the applications we were using, it was less than a two-year payback.”

Hamil says this kind of ease has developed in the last two decades. In the past, she says systems were “extraordinarily expensive and complicated, and may have been more temperamental. Today’s systems are robust and easy to use.”

Industry Integration

As for why there isn’t wider acceptance throughout the industry, she blames a ‘fear of the unknown,’ though for some produce handlers it may be a lack of knowledge as well as the initial costs.

Which is usually the case with new technology until enough people catch on. “While there’s a strong business case for ROI [return on investment] on equipment,” McGrath finds that ozone is, “for lack of a better term, the ‘insurance policy’ for safer food.”

More importantly, McGrath stresses, “The big issue is doing everything you can do operationally to protect against a recall or being associated with any sort of foodborne illness.”

Hamil agrees, believing the combination of social media and increased Centers for Disease Control oversight has not only brought more outbreaks to light in recent years, but has helped food safety experts better track incidents across the nation. “Data is captured and logged so much more efficiently than twenty years ago,” she notes.

The Future of Ozone

According to Codiga, ozone use is growing in other countries such as France, Australia, and Japan and predicts it will become the norm for all agricultural products in the years to come.

Hamil has similar thoughts. “I’ve done this for 38 years,” she notes. “I can’t tell you how many thousands of times people have said it sounds too good to be true. I’ve made it my life’s work to be an ozone educator.”

Looking ahead, Hamil can envision costs coming down, though she cautions too-low pricing could be a red flag and signals an inferior ozone system.

As people in the industry learn more and gain a better understanding of the concept, she believes they will not only get on board, but become loyal users. “Those who have used ozone and bought systems from a reputable company,” Hamil contends, “would never go back.”

Basciani Foods seems to be a good example of such a company. “We’re not 100 percent ozonated, but we’re pretty comfortable where we are. We’ve reduced chlorine use by about 80 percent.”

McGrath sees the future in not just produce, but in expanding ozone sanitation of water.

“We’re going to be able to capture whole facility water and recycle it, ozonate it, and return it to the facility like we do currently with municipal wastewater. As water becomes a bigger and bigger issue, reuse and recycling of facility water becomes a bigger issue.”

The Environment and Chemical Usage

The Environment and Chemical Usage