A framework for reviewing reefer downloads

Temperature control issues are an everyday fact of life in the fresh produce industry for vendors and carriers alike.

Sellers warrant that their product will arrive at the contract destination without abnormal deterioration provided transportation conditions are normal (see 7 CFR 46.43(j)).

Consequently, buyers typically need to show normal air temperatures in transit to prove a breach of contract by the seller. And, of course, if temperatures appear to be abnormal, carriers can expect a claim to come their way.

If you’re a produce industry veteran who handles claims on a regular basis, you’re probably familiar with Blue Book’s rule of thumb for assessing readings from portable recorders.

Section (6.2) of our Transportation Guidelines provides, in part—

Slight deviations in transit temperature based on, among other things, the location and accuracy of the temperature recorder, are inevitable and permissible. What constitutes a “slight deviation” will vary, but as a rule of thumb temperatures within the trailer should not deviate more than four (4) or five (5) degrees Fahrenheit from the agreed-upon transit temperature.If a temperature range is specified, any deviation will be assessed from the midpoint of the specified range. A temperature variance lasting less than twelve (12) hours may also be categorized as a slight deviation, depending on the extent of the variance, the relative perishability of the commodity, and other circumstances; e.g., a shipment involving multiple pick-ups or drops may be expected to experience temperature variance during loading and unloading. Nothing in this Section should be interpreted to suggest a temperature deviation was slight, and therefore permissible or excused, when product has been frozen in transit.

It’s important to remember, however, that this rule of thumb is based, in part, on USDA Perishable Agricultural Commodities Act (PACA) precedent assessing “normal transportation conditions” from portable recorders prior to the advent of reefer-based temperature logging.

Today, portable and reefer-based temperature readings both play a role in most of the claims we see. In this article we review portions of a download from a recent claim and discuss the framework Blue Book uses when assessing reefer downloads.

Reefer Downloads

While portable recorders are commonly attached to shipping cartons in the rear of the trailer, the temperature sensors on the reefer unit reside on the unit itself.

They’re in the nose of the trailer on the reefer-side of the return air bulkhead wall—separated from the produce—and in close proximity to the unit’s refrigeration coils.

Also, unlike readings from portable recorders, reefer units respond and adjust to readings captured by the unit’s temperature sensors.

As a result, reefer downloads tend to report significantly cooler return air temperatures than portable recorders placed in the same trailer and cannot be assessed in the same manner as readings from portable recorders.

Based on the claims placed with Blue Book, we generally expect to see (i) return air readings within one degree of the set point, with (ii) supply air temperatures within 4 to 5 degrees of the return air readings.

Usually, when reefer readings exceed these figures, it’s during the warmest part of the day, calling into question the adequacy of the trailer’s insulation.

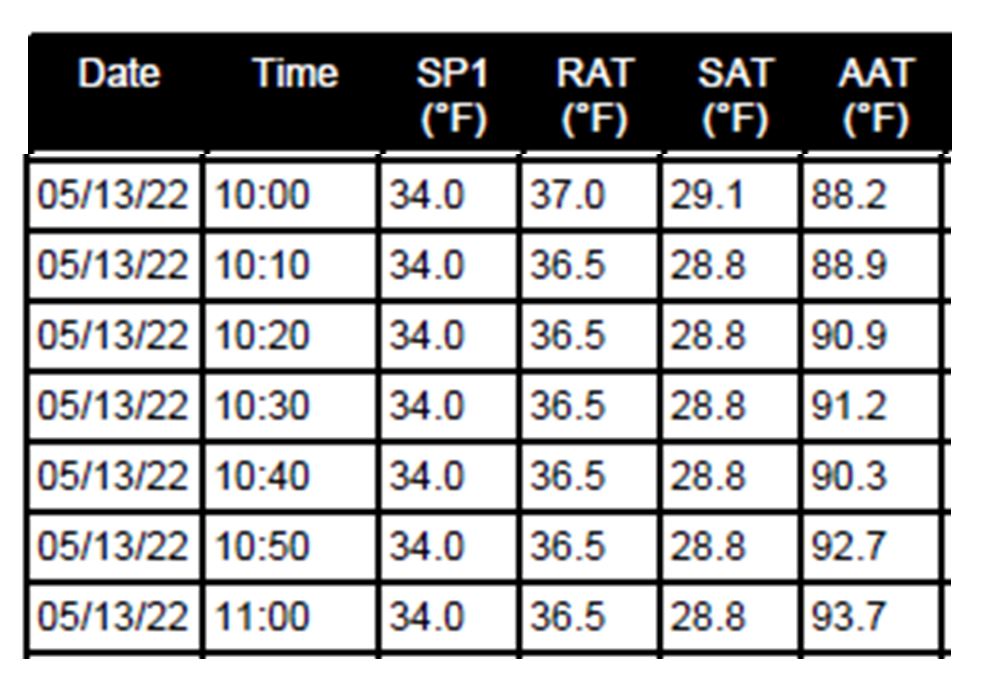

However, in the first download example (below this content), we see that even in the early morning hours of May 13, 2022 (with outside temperatures between 68 to 72 degrees) these limits were being tested.

The return air readings were running 1.2 degrees above the set point, and the difference between the supply and return air readings were already approaching 6 degrees.

And as outside temperatures increased by mid-morning, the return air temperatures increased to 2 to 3 degrees above the set point, while the difference between the supply and return air readings increased to between 7 and 8 degrees.

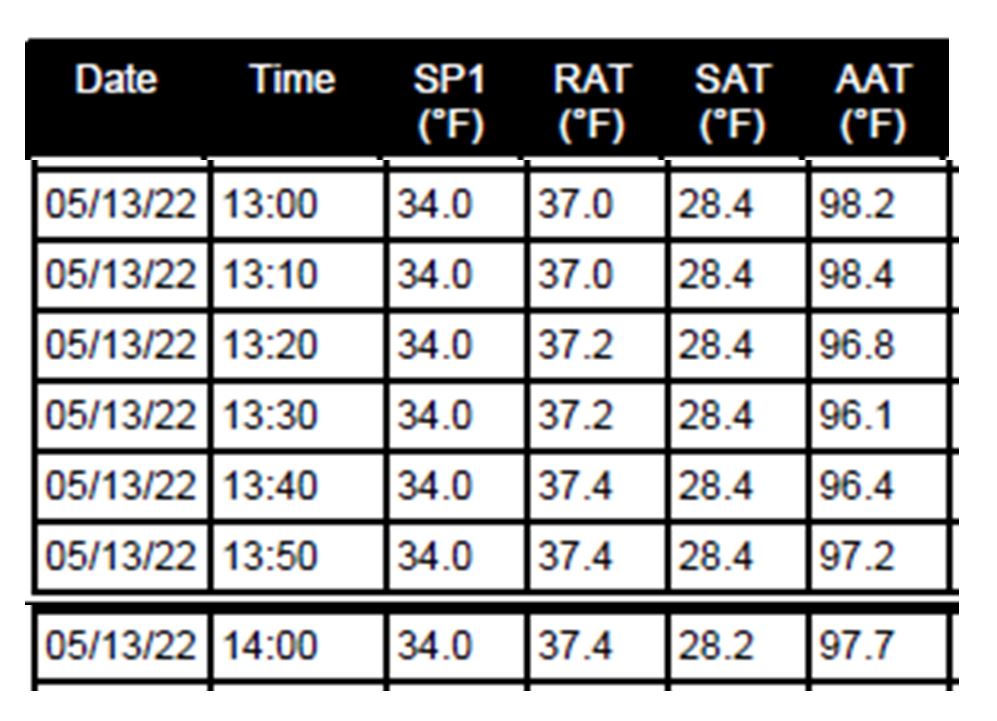

Then, during the hottest part of the day, these figures climbed well above what we would consider normal with return air readings 3 to 3.5 degrees above the set point, and the difference between the supply and return air readings increasing to 8 to 9 degrees.

Understandably, produce buyers will sometimes apply the rule of thumb Blue Book uses to assess readings from portable recorders to reefer downloads. Doing so in this instance might lead to the conclusion that air temperatures in the trailer were normal.

As explained in Section (6.2) of our Transportation Guidelines (quoted at the beginning of this article) a 3- to 3.5-degree variance between the instructed air temperature and the readings from a portable recorder does not normally raise a red flag.

But where reefer downloads are concerned, return air temperatures 3 to 3.5 degrees above the set point, for hours at a time, must be considered abnormal for a reefer unit set to run continuously (as of course it should be when hauling fresh produce).

With respect to carrier claims, it must be remembered that under the common law of common carriage, when shippers make their prima facie case by showing good condition at shipping point (usually with a clean bill of lading and any statements or records from the shipping warehouse) and damaged condition (with a USDA or CFIA inspection certificate) at destination, carriers, in order to defend against the claim, are required to show both shipper error (or one of the other rarely used defenses, e.g., act of God) and “freedom from negligence.”

Given the temperature control issues suggested by the reefer download here, we suspect the carrier would have a difficult time proving freedom from negligence in this instance.

Of course, others may feel this framework for assessing reefer readings is too strict, or not strict enough, or perhaps too simplistic. And we can’t assume that the reefer’s temperature sensors are perfectly calibrated in every case.

But, at minimum, we think this framework is a useful starting point for evaluating the streams of data provided by reefer downloads more objectively and more meaningfully.

As always, we welcome your feedback.

This is a Trading Assistance column that appeared in the November/December 2022 issue of Produce Blueprints Magazine. Click here to read the whole issue.